One of the most popular methods when it comes to printing, if you don’t know much about the printing process, then the sublimation technique may sound complicated! However, the results it derives are divine, more so when it comes to those more detailed designs.

Sublimation printing encourages a higher quality image every time and veers as closely to the original image as possible. Furthermore, this image will retain and hold its high quality for a long time afterward.

Here we offer a practical insight into the process of sublimation printing, highlighting why so many designers are turning to this fantastic process.

Sublimation Printing in a Nutshell

In its more scientific terms, sublimation printing is a chemical process whereby solids are turned into gasses, without the need to enter a liquid stage.

Yet, in its more simplistic of terms, it’s merely a printing method allowing you to transfer images onto the most suitable of materials!

A popular printing choice, you may also hear it referred to as dye sublimation printing. Either way, the process is entirely the same.

This printing method has caused a hype in the design industry for the sheer fact that it veers away from typical old fashioned types of printing processes. Whereas before you would typically incorporate water into one of the printing steps before arriving at the gaseous element, with sublimation printing, the liquid phase is abolished!

Thus, you can go straight from a solid to a gas, and it’s all because of the chemical reaction provided, similar to that of dry ice.

The Process of Sublimation Printing

With the boring stuff out of the way, you may now be wondering exactly how this fascinating technique works in action? This is the smart part and where sublimation printing really comes into its own!

In short, the sublimation printing process essentially brings heat and ink together to combine as one, via the use of heat.

- A digital printer produces images on sublimation paper – it does this via the use of sublimation ink

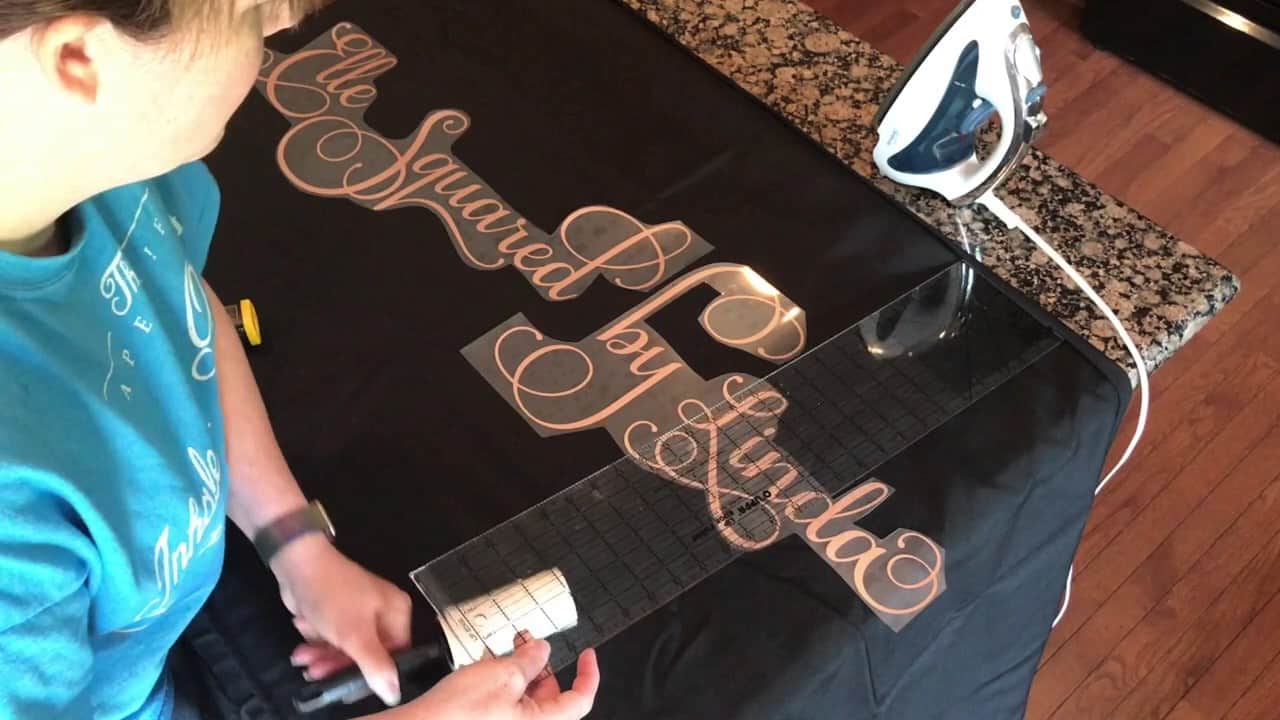

- This paper is placed into a heat press

- The material is thus exposed to the highest of temperatures – at around 350 to 400 degrees Fahrenheit

- The ink and the transfer material now turn from a solid to a gas

- In the gas state, the material fibers are permeated

DON’T MISS: Best Sublimation Printers available today.

Fabric Choices Available for Sublimation Printing

When it comes to selecting a fabric to use, only certain material types are suitable to use with the sublimation process.

These include 100% polyester materials or those materials that have a special coating of polymer.

In addition to the fabric type, color is also a critical consideration of this printing process. Therefore, the best options here are those white or lighter colored fabrics.

The Potential Pros and Cons of Using the Sublimation Printing Process

As with any printing technique, what works for one won’t necessarily do so for others. The same applies to the sublimation printing process. Here are a few pros and cons to this method you may want to consider before making your decision as to its effectiveness for your own designs.

Need new premium T-shirt designs? Get 5 for free from Tee.design

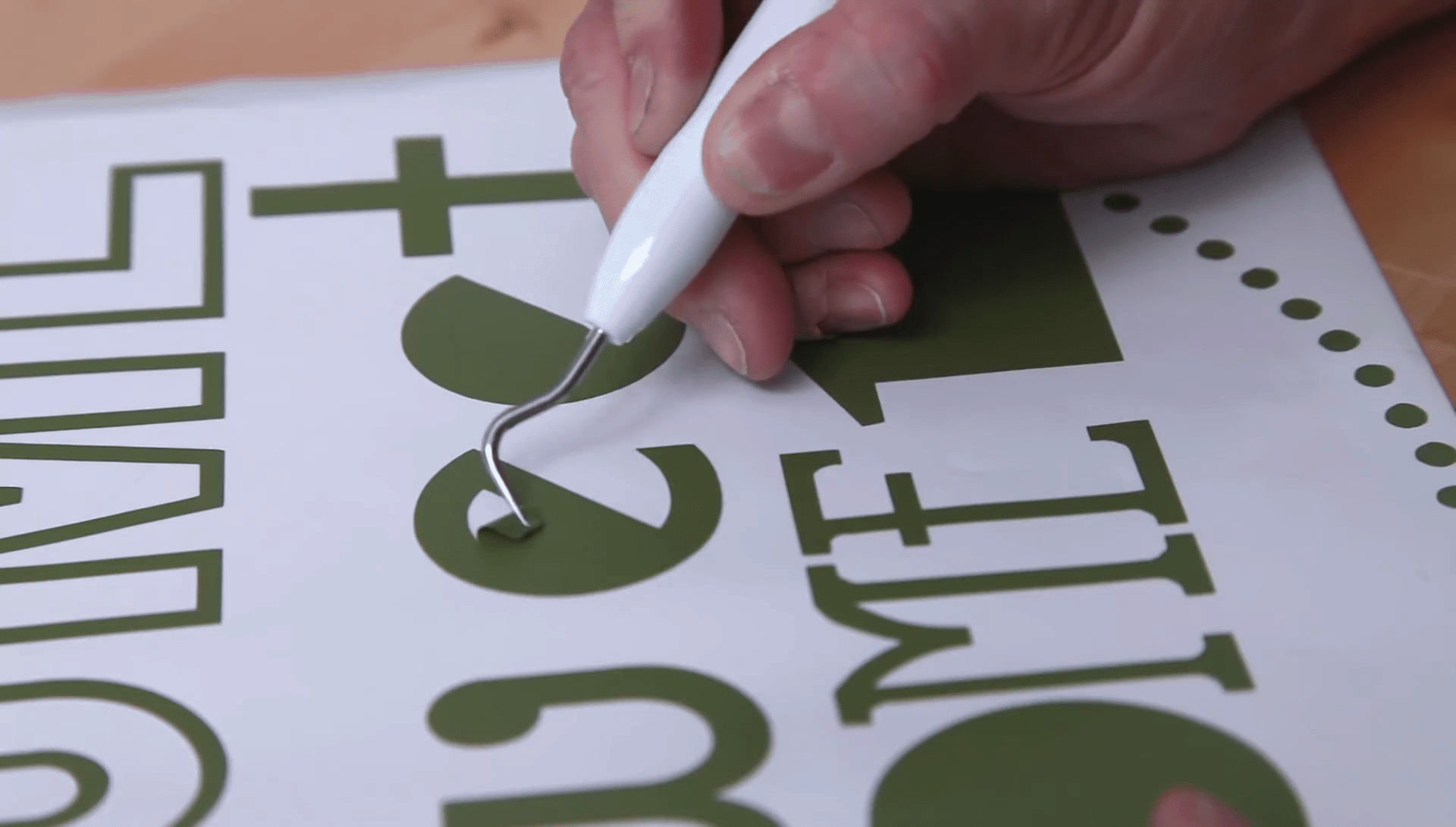

- The process of sublimation achieves the finest and most photorealistic of images, especially when it comes to detail

- Allows for the more complicated of designs

- Is easy to use when setting up

- Can be used to create mugs, coasters, and mouse pads, to name but a few

- Ideal for those smaller items regarding costs, times, and production methods employed.

- Perhaps top of the list here is that lack of material choice which means using only 100% polyester or unique polymer coated fabrics

- The cost of this specialist printing technique is often quite high

- It will require a heat press, sublimation paper, and the essential software.

Designs that Work Well Using the Sublimation Process

For the most effective results, there are a few designs that are more suited for this type of printing process including:

- Quirky designs

- Dramatic designs

- Ridiculous designs

- Full designs

- Vibrant color ranges

- Repeated motifs

- Photography prints

Final Thoughts on the Sublimation Printing Process

Ultimately, this is one printing process that is perfect for encouraging more freedom with your designs – something not always offered by other methods.

Thus, you can let your imagination soar here and then revert to a more classical design choice whenever you want a change in pace. Either way, the possibilities here are endless.

What’s more, the final designs, mainly when used on longer-lasting materials, encourage a no peeling, no cracking, and no fading end result.

So, if you’re looking for the most durable of printing techniques, the sublimation printing method may just be the perfect one for your creations.