Personalized t-shirts have always been popular and they never seem to go out of fashion. Many people prefer to create their own designs for their own personal use, while others set up a t-shirt printing business.

T-shirt printing is big business these days, and there are many t-shirts printing methods available. Most of these methods can be carried out at home or as a business, and all create wonderful t-shirts to keep or sell. If you’re not sure how to go about printing your t-shirts, then this article will explain some of the pros and cons of the most popular methods.

The good news is you don’t need to be able to draw and you don’t need to be technically minded. Anyone can print t-shirts with the right equipment and a bit of practice, but finding the best t-shirt printing method to suit you may take some investigation and a little practice.

Screenprinting

Screen printing is a popular choice with t-shirt makers, but it does require patience and practice. A lot of companies prefer to use this method, and there are many different types of screen printing techniques.

What You’ll Need

This method does require a lot of equipment and it also needs a fair bit of space. To get started you will need:

- A screen and a frame

- Photo emulsion and sensitizer

- A desk lamp and a 250 watt bulb

- Latex or rubber gloves

- Transparency paper

- A squeegee

- Specialist silk screen fabric ink

- A pitch black room such as a dark room or a large closet

How Does It Work?

The first thing you do is create your image. This is done using readily available software such as Photoshop or CorelDraw, but unlike most images you just want to create a silhouette. Your finished image will be printed on to transparency paper and used to black out parts of the screen, so you simply need a black outline.

You then coat the screen with emulsion and sensitizer, and this is then left in a dark room to dry. This process can take a good couple of hours. When the screen is dry, keep it in the dark and using masking tape, fix your transparency to the screen. Place the 250 watt bulb in your desk lamp and angle it so it is 1-2 feet away from the screen. There should be no other light in the room. After 15 minutes, turn off the lamp and you should see lines where the image has burnt on to the screen.

Clean the screen using water, leaving just the burnt on image. The screen needs to be completely dry, then you can spread the inks over the screen. With your t-shirt laid out underneath, use the squeegee to press the ink through the screen. When your image has transferred, hang the t-shirt to dry.

Once the screen has been prepared it can be used over again for as many t-shirts as you like. When you have finished with that image the screen can be cleaned and reused.

Free Gift: 5 Premium T-shirt designs from Tee.design

Pros and Cons

- Cost: Screenprinting does require a lot of equipment, but most of it can be bought from art or craft stores so you don’t have to spend a large sum

- Ease of use: It can be very time consuming creating each print and you will need to practice before you get the process right. Once an image is set up, it’s straightforward to mass produce t-shirts.

- Space needed: The big drawback to screenprinting is that it does require a totally dark room, but it can be run from home.

- Home use v commercial: Perfect for both home use and commercial use.

Direct to Garment or DTG

Another of the t-shirt printing options available is direct to garment printing, or DTG. This method is quite new to t-shirt printing, and is more suitable for those looking to print t-shirts as a business, rather than for home use.

What You’ll Need

- A DTG printer

- Printer inks

How Does It Work?

The process involved in DTG printing is quite simple. You design and create your image in the same way as you would for a printer. You can use any image editing software to do this, so it doesn’t have to cost a lot.

With a DTG printer, instead of printing your image on to paper or transparencies, you print the graphic straight on to the t-shirt. White t-shirts work best with this printer, and it does take practice to print on to darker shirts.

The printer is designed to feed the t-shirt through in the same way as it would feed paper to print on. It is a quick and simple way to create quality t-shirts in minimal time and it can produce one off designs as cheaply as it can fulfil a large order.

Unfortunately, due to the cost and size of the printer, this is not an option for those wishing to produce smaller quantities of t-shirts or work from home. It is a great investment for anyone looking to set up a t-shirt printing business as its speed and versatility means you can fulfil both large and small orders easily.

The finished product is not quite as good as some other methods, but it does produce multiple colours and creates a lovely soft image which will last.

Pros and Cons

- Cost: DTG printers are very expensive and so they are not a suitable option for anyone setting up a business on a budget or for anyone looking to make t-shirts for their own use.

- Ease of use: Easy to use as there is no other equipment involved.

- Space needed: The printers are quite large and are best suited to a commercial environment.

- Home use v commercial: Cost and size make it impractical for home use, but it will produce one off designs as easily as it produces multiple ones.

Sublimation Printing

Sublimation printing is another of the types of t-shirt print available and it is a good option for both small users and commercial users

What You’ll Need

- A sublimation heat press

- Sublimation inks

- Heat transfer paper

How Does It Work?

When you use sublimation printing you first need to create your graphic using image editing software. If you prefer you can scan a photo or drawing in to your software as well.

The design is then printed on to special transfer paper, using ‘mirror image’ or ‘reverse image’ as a printing option. Unlike other printer options, if you want the best result you will need to use sublimation inks. These are designed to sublimate at temperatures usually associated with a heat press.

The print is forced into the fabric, rather than printed on top of it, so the image will stretch as the fabric stretches. Sublimation is, therefore, the best option for large or all over designs.

Once you have your image, you need a sublimation heat press, which is designed to work with sublimation inks. The combination of heat and pressure forces the ink on to the fabric, and all you have to do is make sure it is set to the correct settings.

The cost of a sublimation heat press is more than other presses, but if you are considering setting up a t-shirt business, it may be worth investing in, particularly if you are going to be printing larger designs. The one drawback is that it works best with shirts which are made from 100% polyester.

DON’T MISS: Our 5 Recommended Sublimation Printers!

Pros and Cons

- Cost: The cost of a sublimation heat press means it is more suited to those looking to make t-shirts on a commercial basis, rather than for home use.

- Ease of use: The process is easy to follow and easy to set up, so beginners can use this method as well as more experienced t-shirt designers.

- Space needed: Sublimation heat presses vary in size, and if you want a heat press which will produce an all over design, then it will take up a lot of space.

- Home use v commercial: This method can be used for both home and commercial use, but is a little more costly to set up for home use.

100% free download: 5 premium T-shirt designs from Tee.design

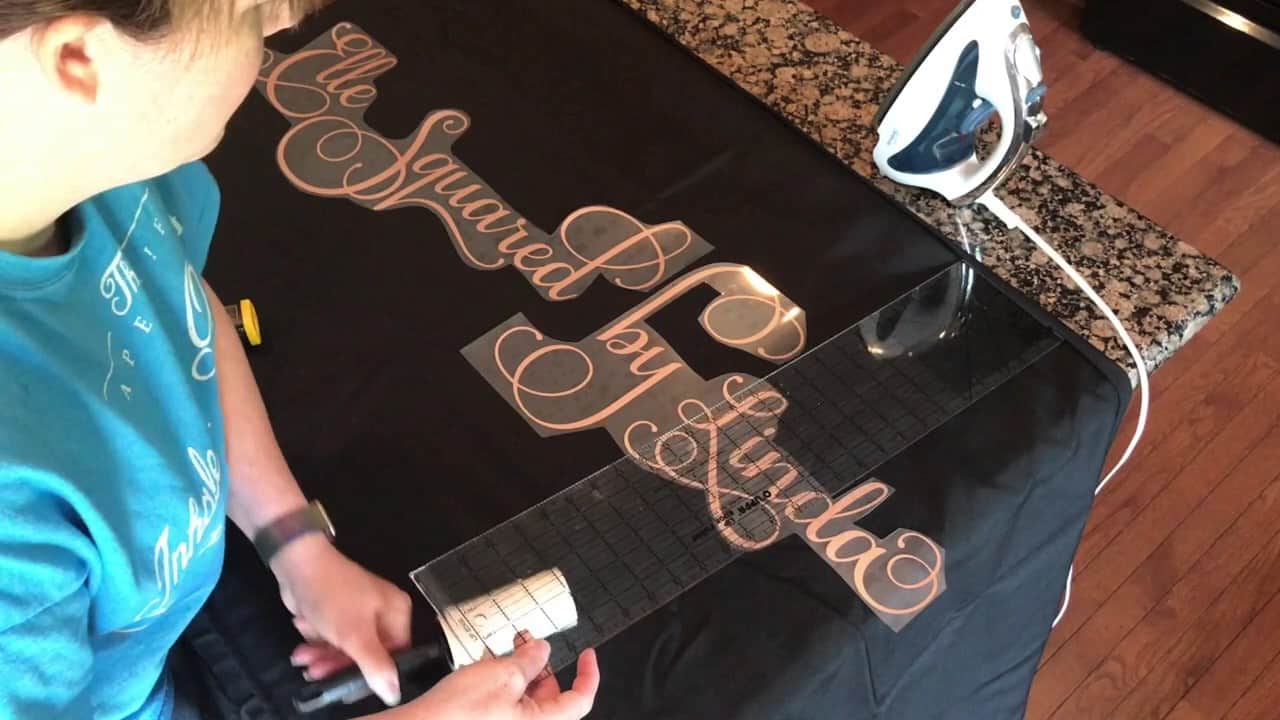

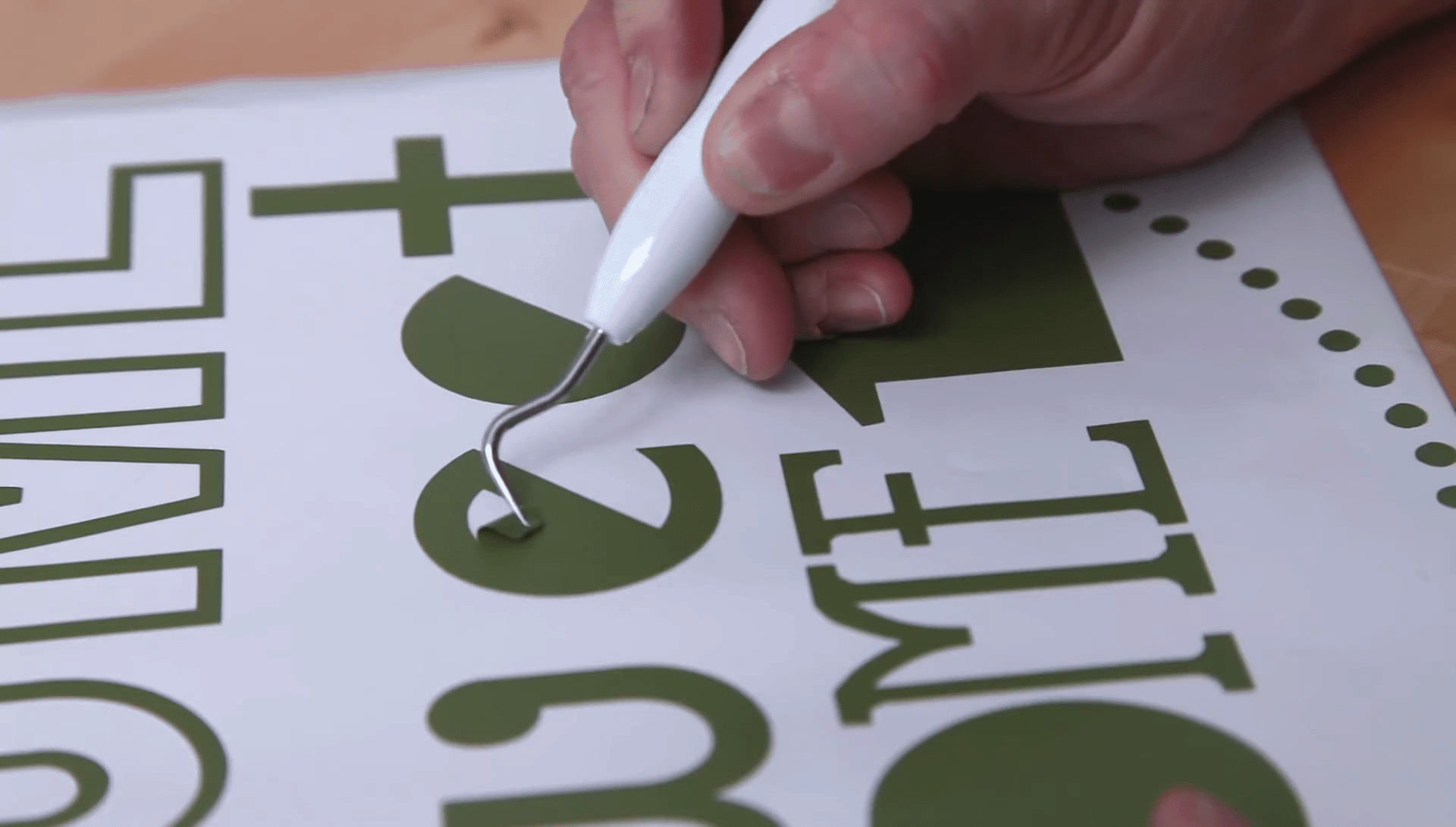

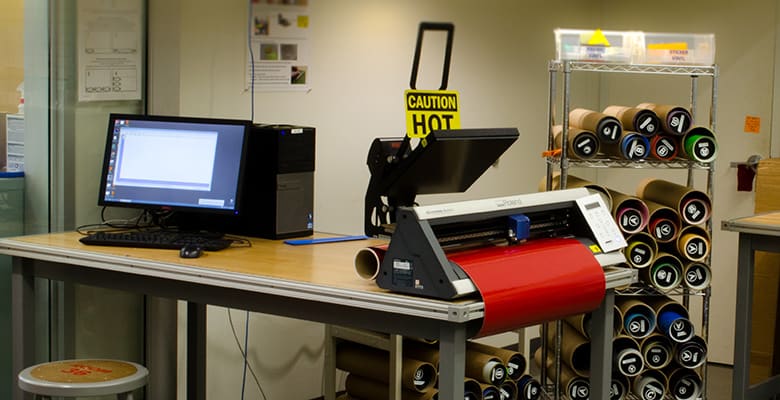

CAD Cut Vinyl Printing

Vinyl printing is an alternative to transfers and needs more equipment to use. The vinyls produced can also be used as stickers for other materials.

What You’ll Need

- Vinyl cutter

- Heat transfer vinyl rolls

- Image software

- Heat press

How Does It Work?

CAD cut vinyl printing combines a vinyl cutter and a heat press.

Your image is prepared using Image editing software, though some vinyl cutters will require the use of Vector Imaging software. This image is then sent to the vinyl cutter, which cuts the required shape out of your vinyl.

The vinyl comes in rolls, so it must be cut to size before you print. When the vinyl cutter has cut out your design, you peel away the excess vinyl around the sides. The cutter can only cut out an outline, so if you have letters or numbers you may need to cut away the middle of these with a craft knife.

The finished vinyl is then attached to the printer using a heat press. This should be heated to the right temperature, and you will receive a guide to help with this in with the heat press. Once it has reached the desired temperature you can press your t-shirt.

Place the t-shirt over the lower plate and place the vinyl face down in the right position. Lower the top plate and lock the handle in place to complete the process. When the time has elapsed, your transfer should come cleanly away, leaving your vinyl in place.

The finished vinyl is not as flexible as some other methods and you are limited in your designs as you can only cut one colour at a time. It’s a good choice for sports wear or logos.

Pros and Cons

- Cost: For this method you will need to purchase both a heat press and a vinyl cutter so it is a better choice for anyone looking to set up a business.

- Ease of use: The process is quite easy to operate but cutting the vinyl may require a little practice.

- Space needed: Having both machines means you will need more space than you will for some other methods, as you need room to move around both pieces of equipment too.

- Home use v commercial: Given the cost and space required, it is more for commercial use, particularly for someone looking to specialise in sports wear.

Transfer Paper

Heat transfer paper has been used for many years and is now an efficient and easy way to print t-shirts for home or commercial use.

What You’ll Need

- Heat press

- Transfer paper

- Printer

- Computer

- Image editing software

How Does It Work?

Working out how to print t-shirts using a transfer is quite straightforward for those new to designing t-shirts. To create a t-shirt using transfer paper you will need image editing software to create your image. Free software is available or you can purchase a software package. When you have your graphic ready, it is then printed on to heat transfer paper using a normal ink jet printer, or you could take a look at our article on epson printers specifically for heat transfers.

The image should be printed using ‘mirror image’ or ‘reverse image’ as it will print out back to front on the t-shirt.

The heat press is heated up to the desired temperature, which will vary depending on your chosen fabric. Every heat press should come with a guide so you know how hot it needs to be and how long you need to allow for the transfer to take.

The t-shirt is pulled over the lower plate, which is usually the cooler plate, with the transfer placed face down on top. The press is then closed and locked in place while the image is transferred to the t-shirt.

One big advantage of a heat press is that it is a good choice for anyone looking to make their own t-shirts at home as well as for anyone looking to run a business.

Need designs to print? Get 5 premium designs for free from Tee.design

Pros and Cons

- Cost: Heat presses are available in all price ranges so if you are looking for one for home use, you will find one within your budget. Higher specification ones are available for more commercial ventures.

- Ease of use: This is an easy method for anyone looking to start out, as the machine does most of the work for you.

- Space needed: Most heat presses take up minimal space, but you do need to allow room to move around it. They can be placed in craft rooms and dens at home.

- Home use v commercial: A good choice for either thanks to their cost, size and ease of use.

Conclusion

Deciding which is the best t-shirt printing option for you will depend largely on whether you are planning to make your own designs at home or sell them commercially.

Not all methods are suitable for home use due to their size or cost, and in most cases, it’s a good idea to see if you can try it out before you invest a lot of time and effort in to something which isn’t for you.

With so many options available there is bound to be a method that suits you and how you intend to create your t-shirts.